Machining and welding for construction machineries

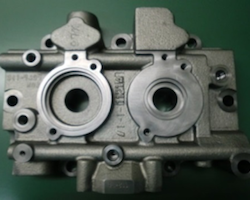

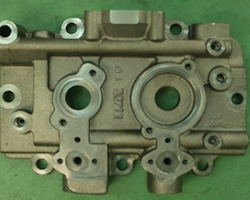

Workpiece for hydraulic and power transmission equipments

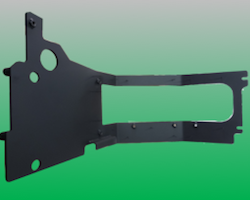

Machining and assembling products for forklift truck

We promote the modularization by subassembly.

We have established a system which corresponds to all processes from purchase of raw materials to quality control and suggestion for improvement.

1. Purchase

- We are able to purchase all casting and fusion cut steel plates regardless of the materials and its shapes.

- Our global purchase enables our customers to reduce the time and cost.

- We collaborate suppliers in order to produce the quality products.

2. Design of jig tools and process

- We design and produce all jig tools which are needed for manufacture.

You don't have to worry about the design of complicated jig tools which require high accuracy.

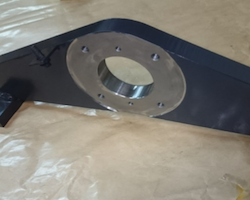

3. Welding

- We consider the deformation in the process of welding, and make products by our craftsman's hands.

- Nondestructive inspections are conducted in order to keep the high strength.

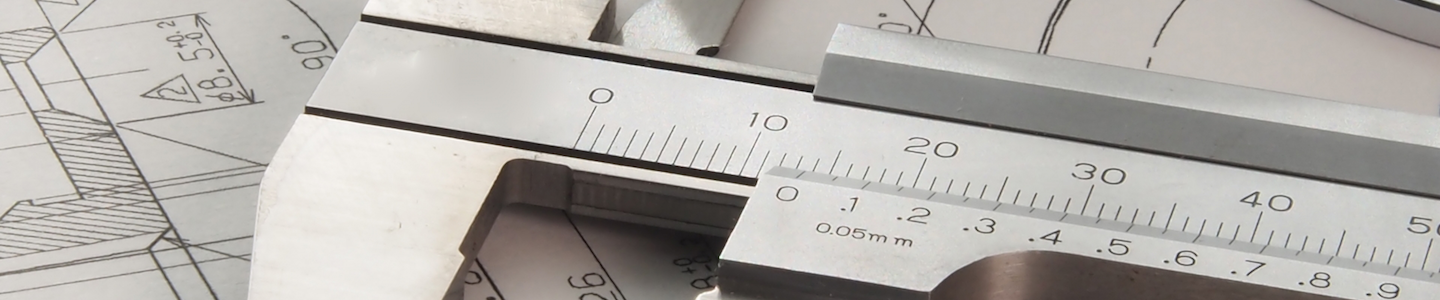

4. Machining

- Our high quality machining processing enables to keep 0.1mm accuracy.

- We manufacture hydraulic equipment parts and conduct the complete inspection.

5. Painting and Assembly

- Products are delivered after the painting and assemble in our factory.

6. Quality Control and Suggestions for Improvement

We have done a lot of improvement by collaborating with our customers.

Case 1) We reduced man-hour and achieved the annual cost reduction (2,160,000JPY) by changing the casting form.

Case 2) We achieved over 30% man-hour reduction in total by reducing cycle-time.